Drilling & Completion Fluids Services

Drill-in-Fluids & Reservoir Fluids

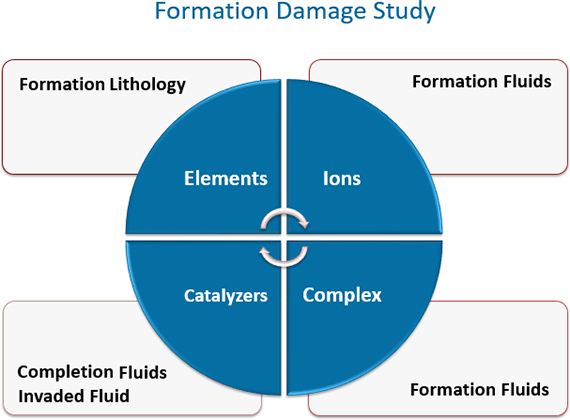

Drilling the reservoir sec on is the most important part of the well in order to minimize the impact of drilling fluids which causes forma on damage and enhance well productivity. We design compatible drill-in-fluids and reservoir fluids based on the reservoir characteristics to make sure production enhancement is optimized.

Reservoir Drill-in-Fluids service is a special service to provide specific fluids designed exclusively for drilling through the reservoir section of a wellbore. With regard that each reservoir is unique and optimizing its performance requires a unique approach, we select a fluid to match the reservoir to mitigate and prevent formation damage, minimize the skin factor and help improve well productivity.

Well Clean Up

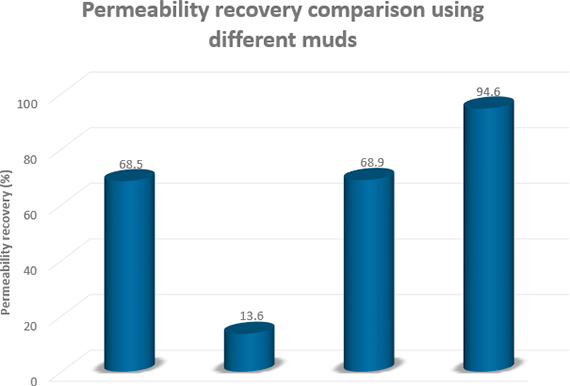

The productivity performance of wells is a crucial endeavor which is directly related to the wellbore damage by drilling fluids. We evaluate the formation damage type and provide well clean up practices, proactive well clean up systems and specialty chemicals to obtain the maximum formation on recovery. Effective removal of drilling damage before putting wells on production maximizes well performance, cash flow and NPV. Well Clean Up services uniformly remove formation damage to optimize well productivity and enables operators to retain and improve permeability in horizontal open hole completions and increase production in mature wells without the need for rig intervention. Well Clean Up services ensure the cleanest wells and maximizes production to deliver significant financial benefits.

Well Clean Up services optimize zonal coverage and achieve uniform radial and longitudinal fluid placement throughout the wellbore, thereby optimizing production from the whole of the horizontal section and maintain and improve permeability all along the pay zone.

Our clean-up systems and mud breakers are customized according to the formation type, blockage degree and targeted productivity.

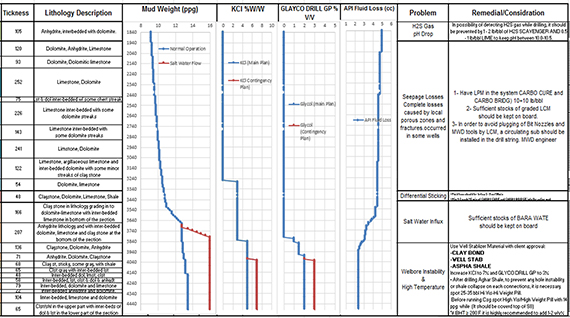

Drilling Performance Monitoring & Optimization

Performance monitoring is one of our engineering services in order to optimize and improve efficiency of the drilling opera on. Based on international benchmarked drilling standards, KPIs and drilling fluids parameters, we will identify the impediments and provide the best possible solution for optimization. We will track and monitor all records relevant to drilling and drilling fluid parameter in order to benchmark and compare the performance during and after drilling. We analysis the followings information for monitoring and benchmarking drilling performance: