Drill-in-Fluids & Reservoir Fluids

Drilling the reservoir section is the most sensitive and important phase of the well. We take a proactive approach to make sure the negative impacts of drilling fluids, such as formation damage are minimized, and by doing so we can enhance the well productivity. We design compatible drill-in-fluids and reservoir fluids based on the reservoir characteristics to make sure production enhancement is optimized.

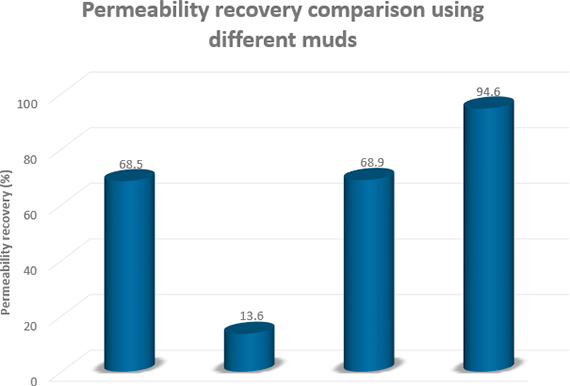

The productivity performance of wells is a crucial endeavor which is directly related to the wellbore damage by drilling fluids. We evaluate the formation damage type and provide well clean up practices, proactive well clean up systems and specialty chemicals to obtain the maximum formation on recovery. Effective removal of drilling damage before putting wells on production maximizes well performance, cash flow and NPV. Well Clean Up services uniformly remove formation damage to optimize well productivity. Furthermore, it enables operators to retain and improve permeability in horizontal open hole completions and increase production in mature wells without the need for rig intervention. Well Clean up services ensures the cleanest wells and maximizes production to deliver significant financial benefits.

Well Clean up services optimize zonal coverage and achieve uniform radial and longitudinal fluid placement throughout the wellbore. It consequently optimizes production from the entire horizontal section, maintaining and improving permeability all along the pay zone.

Our clean-up systems and mud breakers are customized according to the formation type, blockage degree and targeted productivity.